Sewage systems are an essential part of any urban infrastructure.

They need to work 24X7 uninterruptedly across seasons. Any interruption in functioning can lead to a variety of issues like choking of drains, foul smell, etc.

Sewage systems has several sewage pumping stations, a central sewage treatment plant and control/switchgear rooms which are housed adjacent to pumping stations.

Control rooms/switchgear rooms have electrical switches and other costly electrical and electronic equipment used for managing the pumping station.

Specifically, the switchgear disables circuit breakers and other working components to make an electrical system safe for a technician to regulate and control the system without turning it off. Switchgear room components are mostly fabricated of copper, aluminum, and silver compounds.

Safety of the switchgear/control devices is a major concern for Operations and Maintenance. The threat of corrosion coming from the environmental gases generated as a result of sewage treatment may impact the smooth functioning of the switchgear room and plant.

For a good electrical contact, silver is commonly used in the contacts in circuit breakers and in an electrical conductor plating for controlling various operations involved in sewage treatment/sewage lifting.

Sewer gas is a complex mixture of toxic, odorous and corrosive gases such as It includes Hydrogen Sulfide (H2S), Ammonia (NH3), Methane (CH4), Carbon Monoxide (CO), Sulphur Dioxide (SO2), chlorine (Cl2) and Nitrogen Oxides (NOx) which are produced in the sewage treatment process. Removal of these harmful gases is an important aspect for the smooth and continuous running of pumping station and treatment plants.

Bry-Air Gas Phase Filtration Systems are designed for effective removal of toxic gases from control rooms/switchgear rooms. It purifies the air inside the sewage pumping stations/treatment plants through the process of adsorption and chemisorption, in which air is neutralized while passing through a chemical filter ensuring continuous and hassle-free running of sewage pumping station and treatment plants.

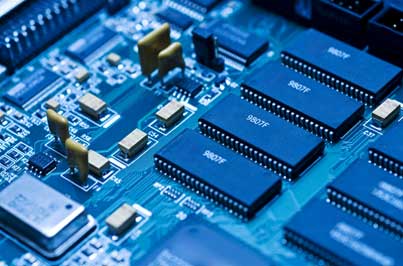

Electronics industry is one of the most dynamic and fast evolving industries. Advancement in technology has led to the electronic devices and gadgets becoming highly sophisticated.

They come loaded with advanced features which are available at a click and at lightening fast speed. The consumer needs are fast changing and so, are the appliances and machines they use. Be it smart phones or control panels of industrial machines, all are becoming more and more complex. The circuit boards, which form an integral part of electronics manufacturing are mounted with more and more components and hence, come along the challenges.

Some of the key problems arising due to high humidity in PCB and Semiconductor assembly are as below:

Corrosion on the circuit surface maximizes electrical resistance and, at the same time, minimize capacitance, which causes adhesion failures, surface defects and decreased performance of the Circuit Board. Humidity control is extremely crucial to:

Moisture also causes problem in the manufacturing of fluorescent tubes, electrical appliances, clean rooms and high voltage cable wrapping. Humidity control measures are to be ensured during capacitor winding and storage, component storage prior to assembly, testing, calibration and packaging.

Bry-Air provides cost effective solutions for your varied dehumidification needs in the electronics industry.

Excessive moisture during manufacturing, assembly and storage of electronic components leads to micro corrosion of Printed Circuit Boards (PCBs), transistor failure, reduced longevity of components, non-uniform growth of crystals resulting in high rejection rate and failure of finished equipment.

Some of successful installations for electronics industry across the globe:

Bry-Air Dehumidifiers provide the ideal low humidity environment for the manufacturing, assembly and storage of electronic printed circuit boards. For PCB & semiconductor assembly manufacture, recommended condition for clean rooms is 20%-35% RH at 20°C (70°F). For increase in speed of batch processing, the RH level to be maintained is around 30-35%.

Bry-Air as a part of its initiative to connect young budding engineers to the HVAC&R industry got students to visit ACREX 2016 at Mumbai and provided them hands-on exposure and learning to the latest in the field of heating, ventilation, air conditioning, refrigeration and building services. The students who were accompanied by their faculty got to interact and understand the latest technologies and relate practically to their studies. This is what one of the students said post his visit -“The event was very good. We got the chance to see the things first time out of the textbook. Very good experience when you join like-minded people across the globe. I got lots of practical knowledge out of this study tour. At the end I like to thank all Bry-Air people to provide us such wonderful opportunity” – Rohan Tote, National Institute of Technology Karnataka, Mangalore.

Mr. Deepak Pahwa, Managing Director, Bry-Air present at the exhibition said – “Bry-Air firmly believes in recognizing and promoting young talent; providing them opportunities to gain exposure and equipping them with the right skill set.”

DRI and Bry-Air were silver partners at ACREX 2016, Mumbai and is also silver partner of ACREX 2017 to be held in Greater Noida from the 23-25 February. The key highlight at the stall was DRI Dew Point Cooler with DRI Cool ultra modules inside that allow the designer to design cooling with reduced energy use, cost savings in air conditioning, improved IAQ and reduced carbon emissions.

The DRI Dewpoint Cooler range will give Indian customers the very best in Green sustainable breakthrough technology locally.

Adsoprtion Chillers – Energysmart Cooling using Waste Heat from Bry-Air generated lots of interest and enquiries from the visitors at the exhibition.

Let's

Get In

Touch