Research And Development

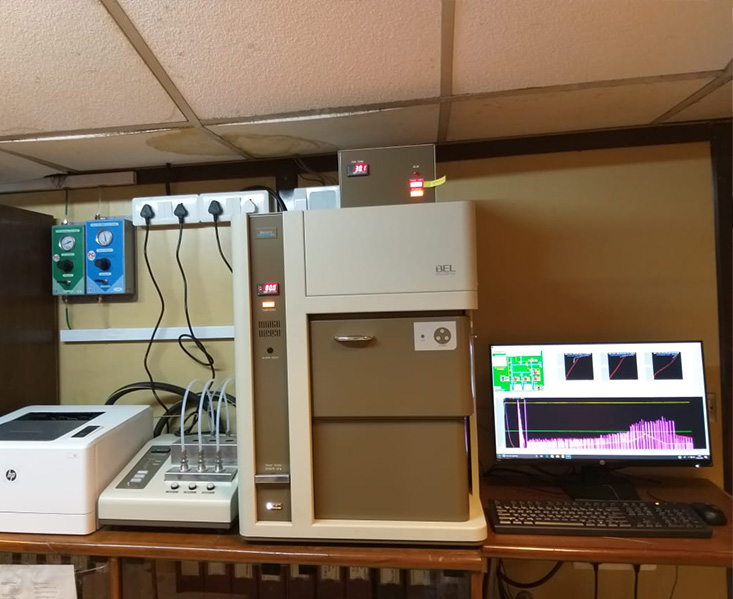

Bry-Air has always been at the forefront of technology and innovation through extensive R&D in moisture control, air treatment and optimisation of energy efficiency. Bry-Air’s efforts to introduce the best in class, energy-smart technologies result in continuous R&D in designs, layouts, machinery and production methods which are integrated into the everyday work pattern. Bry-Air’s position today is a result of its research-driven development strategy.

Bry-Air’s R&D facilities are recognized by the Department of Science and Technology and are the best in the environment control industry, worldwide, in the corporate sector

Pahwa Group with Bry-Air and Desiccant Rotors International (DRI), at its helm is the fastest-growing adsorption technology group in the world.

The R&D at Bry-Air focuses on continuously providing the customer with Energy Smart Green Products through:

R&D on new technologies and materials as well as on controls and sensors

R&D on new technologies and materials as well as on controls and sensors Design standardization through simulation, optimization and globalization

Design standardization through simulation, optimization and globalization Innovative product and process development

Innovative product and process development Testing and certification of products

Testing and certification of products