Deepak Pahwa, Chairman, Pahwa Group & Managing Director, Bry-Air | Energy Storage Pro | Apr-May Issue 2021

Over the years, a lot has been debated around the development of Electric Vehicles as an alternative to fossil fuel-driven vehicles in India. EVs are considered as the cleantech solution to protect the environment and the best source to focus on sustainable development also. They require less maintenance and emit zero harmful gases into the air. Many existing automobile manufacturers and even newer companies are putting an exceptional effort into Electric Vehicles that provides a green and reliable solution.

In India, right from policy makers to manufacturers are keen on improving the EV adopt ion rate in the market, but at this pace, it will take years for EVs to get mainstream. Several factors such as high capital cost, consumer percept ion and inadequate charging infrastructure. But the biggest reason is the driving range and efficiency of batteries. Lithium batteries are considered the soul of EVs and have the highest acceptance in the global market, but in India lead-acid batteries still rule the market.

“INDIA TOO IS MAKING GREAT STRIDES IN THE ENERGY STORAGE SPACE AND THE ACTIVE PARTICIPATION OF THE GOVERNMENT HAS FURTHER STRENGTHENED THE INDUSTRY’S DETERMINATION TO STORE RENEWABLE ENERGY SOURCES.”

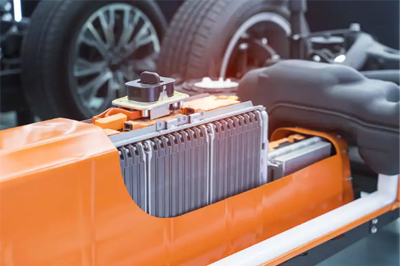

The performance of an Electric Vehicle has a lot to do with the quality of the battery used in it. Batteries consist of several chemical components such as lithium- ion, iron phosphate, graphene and others, which means you need a stable environment with less than 1% humidity, as these particular chemicals are highly susceptible to moisture. Therefore maintaining the right humidity value is key in battery assembling and manufacturing. Lithium battery product ion is under taken in very critical and controlled (Dry Room) environment conditions. Non-maintenance of the desired RH during lithium cell manufacturing (<1%) and battery assembling (<10%) may lead to severe consequences including reduced quality, bad performance, and increased chances of explosion. Excess humidity can lead to costly quality errors in humidity-sensitive applications. Therefore, the process of controlling environmental conditions is essential for the reduction in quality errors.

Desiccant Dehumidification, or moisture control, has proven itself to be a critical factor in the control of the environment in the Dry Rooms without which lithium battery manufacturing is not feasible.

Dry Rooms come equipped with an Environment Control Dehumidification System. These rooms are equipped with moisture control equipment that helps in achieving extremely low dew point [up to (-) 80 °C] control for al l the hygroscopic and moisture sensitive material processing. Lithium and alternative battery manufacturers are today the most vulnerable and hence, are driving the high requirement for Dry Rooms in India and desiccant dehumidifiers across the globe.

On the other hand, India too is making great strides in the energy storage space and the active participation of the government has further strengthened the industry’s determination to store renewable energy sources. To conserve the power generated by these renewable sources ‘Lithium’ is a critical element used in the battery technology that underpins much of the world’s consumer electronics, electric vehicles and energy storage systems.

As per Lux Research, the total energy storage market is expected to grow to $546 billion in annual revenue by 2035. The report also mentions that key innovative technologies, such as sol id-state batteries and f low batteries as they reach commercialization would be the major source of growth.

With moisture control being the most critical aspect of li-ion batteries while manufacturing, technology like Green DryPurge® (GDP) has played a key role in Li-ion battery manufacturing across the world and has helped the

manufacturers in creating the required environmental control to make quality, safe and long-lasting batteries. The ultra- low dew point GDP dehumidifiers have today been benchmarked for world-class moisture control, are cost-effective and are highly energy-efficient, making them a value proposition for any manufacturer.

Suppliers of various desiccant dehumidification products and solutions are playing an active role in India’s EV push and energy storage mission too. Partnering with battery manufacturers/assembler, the role of environmental control solutions offered by local players is instrumental in making reliable and highly efficient lithium batteries in India and across the world.