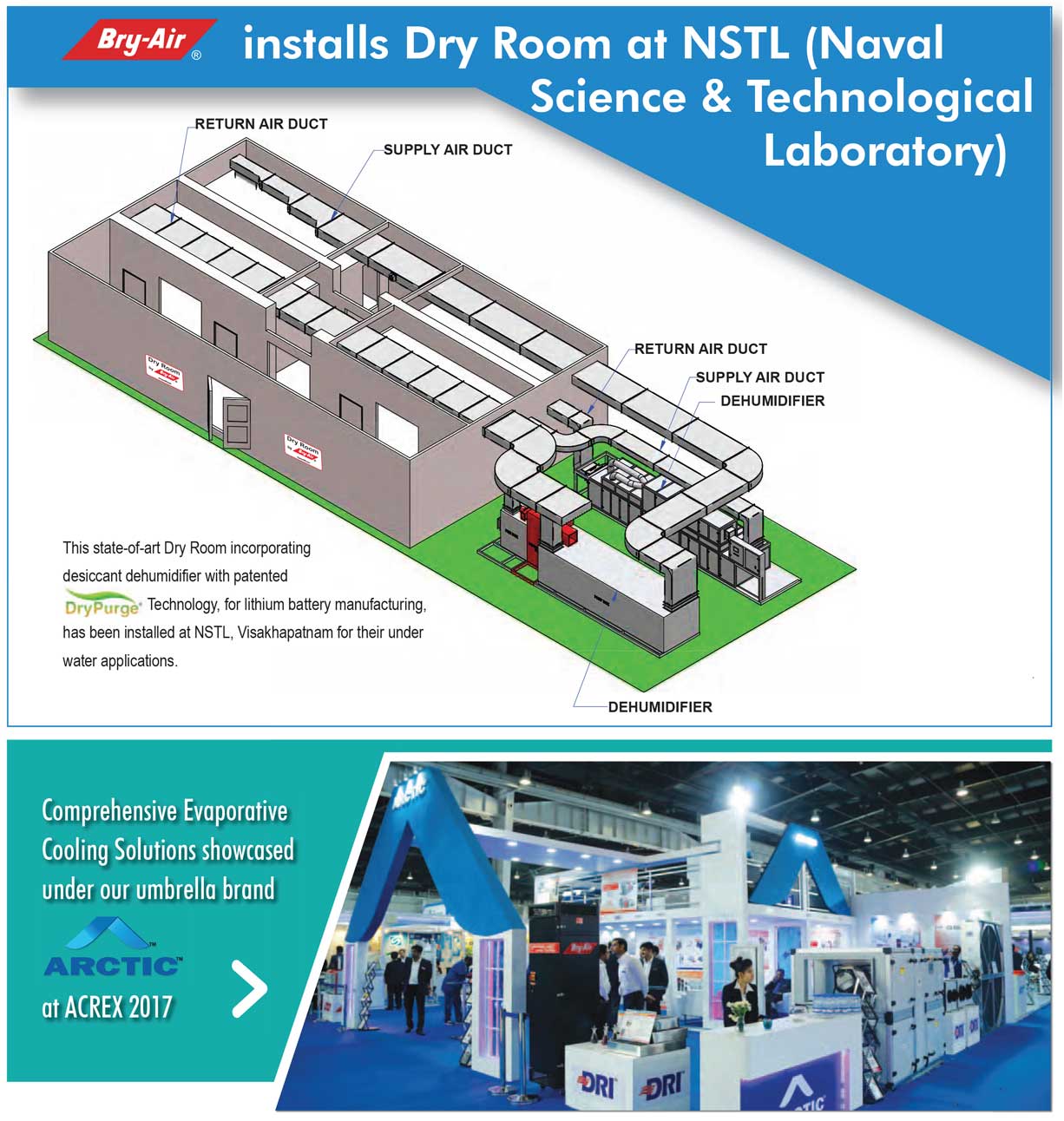

NSTL is located in the coastal area of Visakhapatnam where high moisture level in ambient air interrupts the performance and quality standards of underwater systems.

NSTL uses lithium based raw material, which is highly reactive to moisture, and requires controlled humidity typically less than 1 % RH (-)45°C dew point. Bry-Air, the single source provider, built a fully integrated dry room incorporating desiccant dehumidifier with DryPurge’ Technology, PLC control and integrated data control system.

Lithium and lithium-ion batteries are incredibly efficient and can keep a phone, laptop, electric cars, toys, medical devices and other consumer electronic devices running all day.

Lithium batteries have become ubiquitous over the past decade, powering our cellphones, laptops, ipods, and even cars. Lithium batteries are popular because they pack significantly more energy into a small package, but their chemistry makes them more vulnerable.

When moisture comes in contact with lithium, an exothermic chemical reaction occurs:

2 Li + 2H2O = 2 LiOH + H2 Lithium reacts with water to produce lithium hydroxide and hydrogen

Ideal Dry Room Conditions for Lithium Battery Manufacturing

The air change rate in the production room should be more than 50 air changes per hour with maintenance of minimum fresh air introduction for positive room pressure and ventilation for workers.

recommends to develop stringent environment control chamber for manufacturing lithium batteries (Dry Room) and incorporate patented technology, DryPurge which ensures optimum performance, even at ultra-low dew point, up to (-) 90°C. Additionally, Bry-Air recommends Dry Room to be vapour tight and access must be controlled through an air lock vestibule.