Moringa oleifera is a multipurpose and exceptionally nutritious vegetable tree with a variety of potential uses. It is a sub-tropical species that is

known by different regional names as benzolive, drumstick tree, kelor, marango, mulangay, nebeday, saijhan, mooringai and sajna.

The Problem-Drying the Moringa Oleifera leaves without losing nutritional values

Drying the leaves of Morninga Oleifera is the most critical aspect of processing the product. The leaves should be dried in a place protected from sunlight to prevent the loss of vitamins and minerals. Drying the leaves of Morninga Oleifera is the most critical aspect of processing the product. The drying should be done immediately after harvest to prevent the growth of molds and to achieve the best quality of the dried leaves.

In doing so, MAI incurred very high electricity expenses as they used a huge electric oven, which consumed high amount of electricity to produce acceptable dryness of the product .

Also, the drying process took a long time, which was an added problem. Sometimes, MAI also used organic fuels like “Bagasse” or charcoal but such fuels left carbon on the dried leaves. This conventional method forced MAI to maintain high temperature to make the drying time faster, but this increased the risk of damaging or decreasing the quality of the product since high temperature has negative effects.

Drying the Moringa leaves using a desiccant dehumidifier was highly recommended as the conventional hot air-drying method, was inefficient when it came to large scale drying. Desiccant dehumidifiers maintain quality of dried products by providing constant dry air at medium temperature all year round. Bry-Air Airgineers helped solve MAI’s problems by installing a desiccant dehumidifier to supply dry air directly to their drying room in a 100% recirculation mode (closed loop). A separate air-conditioning unit was provided by MAI to keep the temperature below 40°C to ensure high product quality while drying.

MAI’s decision to shift to desiccant dehumidification resulted in a 200-300% decrease in drying time, which will boil down to costs savings in electricity, while maintaining high quality of the product. MAI is very satisfied with Bry-Air Dehumidifier’s performance and the benefits that came along with it.

Hospital administration focuses a lot on indoor environment not just for safety of patients but also to improve the efficiency of surgeons and provide a better working environment. Moisture sensitive equipment, layers of clothing worn by surgeons, workforce, etc. demand ideal environmental conditions.

High humidity results in more problems than Hospital Managers can imagine!

Using an effective dehumidification solution takes care of the following problem areas:

Discomfort:

Maintaining RH below 60% is recommended for maximum comfort and to minimize perspiration issues.

Safety

High humidity increases microbial growth and risks of infections, musty odor and respiratory issue. Many bacteria and viruses thrive in high humidity and start multiplying over specific RH levels.

Condensation:

High humidity results in condensation on optical equipment, working apparatus and tools, resulting in breakdowns and equipment malfunction.

The recommended conditions for an Operation Theatre Room are 22ºC and 50% RH. In addition to OT rooms strict humidity control is also required in Imaging department (X-ray room, MRI, CT Scanner, Mammography, Ultrasound, Fluoroscopy, Angiology, Tomography), Pathology department (Dark room, biology lab, chemical lab. immunology, hematology). Desiccant based dehumidifiers are extremely effective and economical when it comes to controlling humidity and preventing condensation in Hospitals. Bry-Air, leader in desiccant dehumidification has provided dehumidifiers to some of the largest hospital chains.

For more information, contact us at enquire@pahwa.com

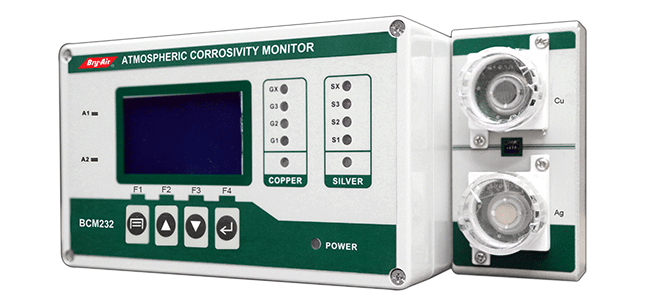

High humidity along with other air laden pollutants result in corrosion and equipment failure. Companies dealing with sensitive IT infrastructure, as a core part of its operations, require safeguarding their equipment’s from the menace and hence, implement a comprehensive check and monitoring mechanism to measure the corrosion potential of gases inside their facility. The ISA standards define or characterize environments in terms of their overall corrosion potential. Bry-Air ACM diagnoses the corrosion of these environment according to the ISA Standard outlining severity of corrosion from mild to severe.

Reactivity monitoring is used to characterize the destructive potential of an environment. It provides an exact and dependable way to evaluate the corrosivity potential of indoor air and also the effectiveness of the installed filter systems.

The ACM model BCM 232 provides real time information on the overall reactivity levels of gaseous airborne contaminants, room temperature, relative humidity and optionally differential pressure.

The usage of this device allows an immediate corrective action leading to increased reliability and reduced maintenance costs of electronic and electrical equipment affected by corrosion.