At Bry-Air, we pride ourselves on being rooted in patented technology, with a legacy of over five decades in dehumidification and environment control solutions. Our commitment to innovation and excellence has led to the development of cutting-edge desiccant and adsorption-based technologies at the heart of it.

Bry-Air focuses on unveiling moisture-related challenges and providing tailored solutions to each of the key problems. Here, we provide detailed insights into industry-specific issues, like excess humidity impacting product drying in Food Processing and Pharmaceuticals, and many more.

01

Product drying is a critical step in various industries that play a vital role in preserving, enhancing, and transforming a…

view more

view more

02

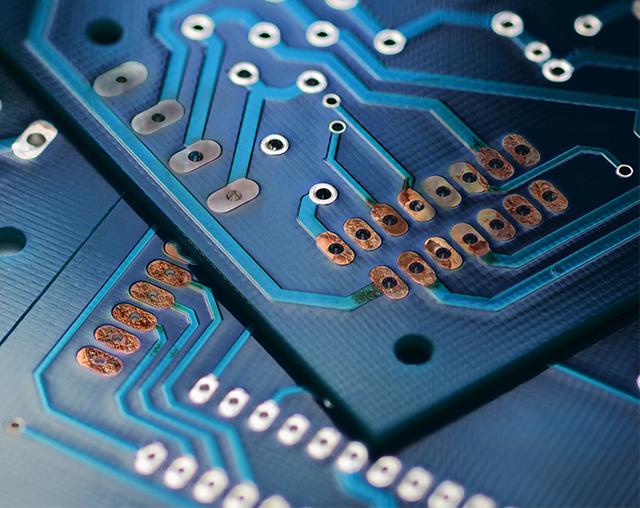

Electronic corrosion, or electronic component corrosion, refers to the degradation or deterioration of electronic devices and components due to chemical…

view more

view more

03

Condensation is a common phenomenon that occurs when warm, moist air comes into contact with a cooler surface. This transition…

view more

view more

01

Product drying is a critical step in various industries that play a vital role in preserving, enhancing, and transforming a…

view more

view more

02

Electronic corrosion, or electronic component corrosion, refers to the degradation or deterioration of electronic devices and components due to chemical…

view more

view more

03

Condensation is a common phenomenon that occurs when warm, moist air comes into contact with a cooler surface. This transition…

view more

view more