Cold storage is fast becoming the most sought-after demand driver as the Indian food industry picks up the pace for being an active participant to become self-reliant. In recent times, the Government has developed a number of schemes to boost the cold storage infrastructure, and help the agriculture and pharma industries to solve the problems that paved their way in the growth. Hence, it can be a game-changer for India’s food and agricultural industry.

India wastes tons of food from farms to processing units, and delivery which can be avoided with a better laid cold storage infrastructure. A smoothly functioning cold chain infrastructure includes temperature-controlled storage space, efficient and trained service staff, and transportation.

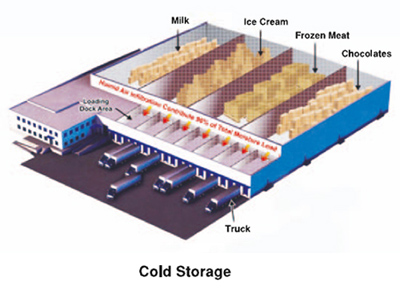

There are two types of Cold Storages available in the market for different requirements per se as, Active Cold stores and Passive Cold stores. Active ones are used for products on daily routines (ice-cream, frozen foods, etc.), have dynamic storage applications, and various temperature zones are created within the same warehouse for storing different products requiring different temperatures. Whereas Passive cold storage is built for storage of perishable goods for a long-term period, for example, storage of seeds, potato, onion, etc.

The food processing industry is one of the largest sectors in India in terms of production, growth, consumption, and export. The cold chain is the backbone for sustaining this scale of food production and processing. However, the major concern is that the agriculture industry loses a considerable amount of produce every year due to various contributing factors. One of the major reasons for the food waste is the lack of an efficient cold chain infrastructure that includes refrigerated transport, pack houses, collection centers, and cold storage. This implies, just having cold storage is not enough.

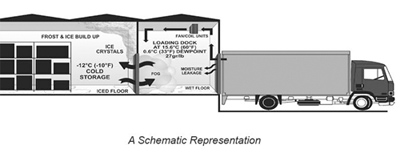

Moisture in your cold stores can cause a series of reactions that can lead to spoilage despite installing the best cold storage. Moisture causes frosted products, slippery floors, ice-build up on conveyor belts, and cooling coils. It leads to frost build-up near the loading docks and fog inside it.

Moisture absorption by cardboard cartons causes softening and sagging that makes them unstable and hazardous. Moreover, humidity puts a burden on defrosting costs, reduced storage space, frequent shutdowns, growth of mold and mildew, and decrease in the cooling efficiency due to water vapor loads and clogging of evaporator coils.

The load is highest at the dock. 90 percent of the total load comes from two sources – Opening of doors and Ingress of fresh air.

Moisture load through ingress of fresh air can be minimized by inducting sufficient fresh air duly dehumidified in the loading dock area to keep dry air moving out of the building even when trucks are docked at the doors. While designing cold stores, typical challenges faced are how to avoid frosting on evaporators, ice build-up on the conveyer.