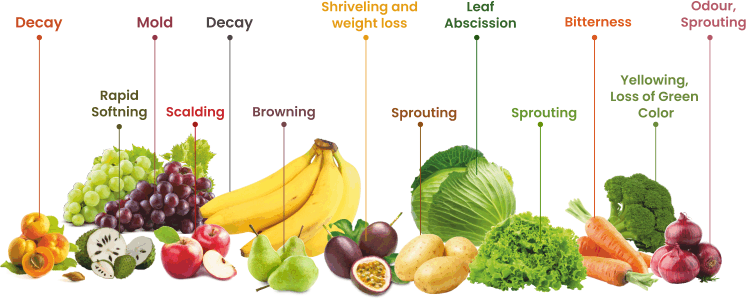

Ethylene Leads to the Over-Ripening of Various Fruits and Vegetables

Ethylene (C2H4) is an odourless and colourless plant hormone in gaseous form, that exists in plants and which is triggered at maturity in fruits. Ethylene is also known as the ‘ripening hormone’ and plays a regulatory role in many processes of plant growth and development.

Being a gas, ethylene can permeate through barriers like corrugated cardboard, and plastic containers and natural barriers like cell walls and plasma walls. When ethylene comes in contact with the ethylene receptors, a reaction on the genetic level starts, depending upon which stage of the life cycle the fruit is in.

Bad Effects of Ethylene on Various Fruits and Vegetables

|

Fruits

|

Ethylene Effect on Fruits

|

|

Vegetables

|

Ethylene Effect on Vegetables

|

|

Apples

|

Scald

|

Potatoes

|

Sprouting

|

|

Grapes

|

Mould

|

Onions/Garlic

|

Odour

|

|

Bananas

|

Decay

|

Carrots

|

Bitterness

|

|

Apricots

|

Decay

|

Green leafy vegetables

|

Loss of colour

|

|

Pears

|

Browning

|

Pears

|

Browning

|

|

Passion Fruit

|

Shrivelling and weight loss

|

Lettuce

|

Darkens and turns slimy

|

|

Cherimoya

|

Rapid softening

|

Cabbage

|

Leaf abscission

|

Fruits and vegetables stored in post-harvest storage facilities, such as cold storage and ripening rooms, require a strictly controlled atmosphere. Uncontrolled ethylene can wreak havoc in these facilities, not only diminishing the quality and shelf life but also negatively impacting profitability.

What Does Ethylene Removal Mean to You?

- A competitive edge with better looking and better tasting product

- Increased customer satisfaction

- Longer marketability of produce

- Decreased shrinkage due to spoilage

- Increase in profitability

- Decrease in rejections

- Reduced waste

Ethylene removal is a harmless process that does not affect the properties of fruits or vegetables.

Gas Phase Filtration System – The Most Effective Way of Removing Ethylene Gas

Ethylene that is released naturally can be continuously removed by Bry-Air Ethylene Scrubber (BES) through the process of adsorption and chemisorption. It extends the shelf life of fruits and vegetables, minimises loss due to decay, ensures off-season availability and eliminates harmful preservation. It also aids in retaining their naturalness and can be ripened as per demand without bearing traces of toxic gases.

Bry-Air: A Step Ahead, Always

Bry-Air is the only Gas Phase Filtration Company in India having its own R&D and Testing Lab for granular media and chemical filters. Backed by world-class technology and systems, the laboratory is capable of testing the performance of impregnated/non-impregnated loose granular media and impregnated/non-impregnated air cleaning devices such as chemical filters, under one roof. The tests are conducted as per ISO/ASHRAE Standard 145.1 and BSR/ASHRAE Standard 145.2/ISO Standard 11155-2 guidelines. The core objectives of the tests are to assess the performance and efficiency of loose granular sorptive media and chemical filters in any particular application.

For any media replacement query, write to us: gpfmedia@pahwa.com