Bry-Air EcoMove BVL Series – Automatic Vacuum Loaders for Plastic Pellets offer large savings to plastics processors, both in terms of man-hours and material by automating the transfer of plastic pellets from shipping containers and storage bins to the processing machines. Engineered for noiseless operation with a sleek and easy-to-handle floor-mounted blower console with efficient filters and controls. The BVL series Auto Loaders allow no leakage and are easy to maintain. Also, it is installed with an easily removable receiver for cleaning, and less and easy maintenance. The compact design ensures that there is no wear and tear and thus needs minimum maintenance.

Bry-Air EcoMove BVL Series used state-of-the-art clear acrylic/polycarbonate receivers/bellies that provided a clear view of the material. It also includes high quality, easily removable filters. It is also available with a transparent flexible anti-static pipe for conveying material.

All loader floor-mount cabinet-style comes standard with:

- CNC manufactured with powder-coated finish

- Micro PLC controller aids loading sequence, auto start and stop of the loading sequence

- Heavy-duty regenerative vacuum pump

- Cartridge-type dust replant high-efficiency paper filter

- Unique silicon and SS flapper design

- CRS receiver belly as optional

- Quick removable clamps for material and vacuum hoses

- Option available for pneumatically operated ratio loading*

- Air and material conveying through highly flexible PVC/PU hoses

- Transparent thunder hoses for visibility of conveying material

- Novel style, mounted on caster wheel for ease of movement

- Audible alarm with a message for faults like material shortage and pump tripped

- Material pick-up tube with adjustable air-to-material ratio

- Option available for pneumatically operated vacuum take off box

- Password protected to avoid any kind of unauthorized handling

- SS Mesh Filter of 530 microns separates the resin from the air in the receiver belly

- Integrated limit-switch activates material demand

- C-Clamp for easy removal of the top hood in the receiver belly for easy cleaning

- Global leader Siemens makes electrical switchgear for safety and reliability

*BVL-1000/1500/2000—Without caster wheels

The Bry-Air Auto-Loader ensures that the hopper is always full. The loader stops loading material once the hopper is full and automatically restarts the loading as soon as the material level inside the hopper falls.

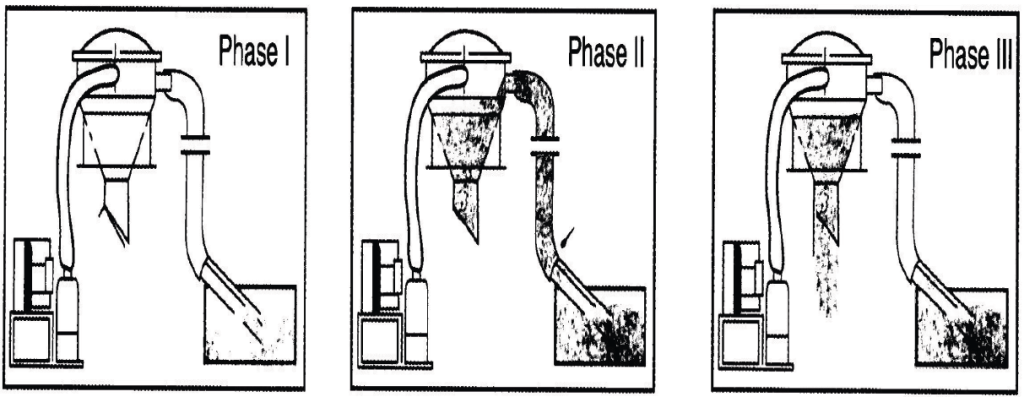

The working principle of the loader is divided into three phases.

Phase-I: When the material in the receiver belly falls below the flapper, the flapper in the receiver belly closes. This triggers the input signal to the controller and after a 10 -12 second delay, pumps start.

Phase-II: The regenerative vacuum pump sucks air from the receiver belly creating a vacuum. Due to the vacuum, material from the bin rises via the flexible pipe connecting the receiver and the material suction probe (the probe remains partly submerged in the bin containing resin/material). An efficient filter between the receiver and the blower filters the air. The loading time is controlled by the controller.

Phase-III: At the present time, the regenerative vacuum pump stops (beginning of phase-III). Due to the weight of the resin, the flapper in the receiver belly opens and the material is unloaded. Once the material is unloaded into the hopper and the receiver is empty the flapper gets closed and the cycle of suction of the material from the bin restarts again with a 10-12 seconds delay (phase-1).

|

Model

|

Standard Accessory

|

|

Material Line

|

VACUUM LINE

|

SUCTION PROBE

|

|

BVL-150 (F)

|

4 Mtrs.

|

4 Mtrs.

|

1 No.

|

|

BVL-250 (F)

|

4 Mtrs.

|

4 Mtrs.

|

1 No.

|

|

BVL-350 (F)

|

4 Mtrs.

|

4 Mtrs.

|

1 No.

|

|

BVL-350 (F)

|

5 Mtrs.

|

5 Mtrs.

|

1 No.

|

|

BVL-450 (F)

|

5 Mtrs.

|

5 Mtrs.

|

1 No.

|

|

BVL-725 (F)*

|

5 Mtrs.

|

5 Mtrs.

|

1 No.

|

|

BVL-1000 (F)*

|

5 Mtrs.

|

5 Mtrs.

|

1 No.

|

|

BVL-1500 (F)*

|

5 Mtrs.

|

5 Mtrs.

|

1 No.

|

|

BVL-2000 (F)*

|

5 Mtrs.

|

5 Mtrs.

|

1 No.

|

The Bry-Air Auto-Loader ensures that the hopper is always full. The loader stops loading material once the hopper is full and automatically restarts the loading as soon as the material level inside the hopper falls.

The working principle of loader is divided into three phases.

Phase-I When the material in the receiver belly falls below the flapper, the flapper in the receiver belly closes. This triggers the input signal to the controller & after 10 -12 second delay, pumps starts.

Phase – II The regenerative vacuum pump sucks air from the receiver belly creating a vacuum. Due to the vacuum, material from the bin raises via the flexible pipe connecting the receiver & the material suction probe (the probe remains partly submerged in the bin containing resin/material). An efficient filter between the receiver and the blower filter the air. The loading time is controlled by the controller.

Phase- III (At the preset time, the regenerative vacuum pump stops (beginning of phase -III). Due to the weight of the resin, the flapper in the receiver belly opens and the material is unloaded. Once the material is unloaded in to the hopper and receiver is empty the flapper gets closed and cycle of suction of the material from bin restart again with 10-12 seconds delay (phase-1).

All Data Subject to Change Without Notice

Ratio loading for resin available and regrind magnetic grills for removal of ferrous impurities. Technical specifications available for twin-loaders are given below.

|

Model

|

Conveying Line Size Dia (mm)

|

Vacuum Line Size Dia (mm)

|

Fiter Type

|

Full Load Amp. at 415/3/50

|

Blower

KW

|

Receiver Belly Dimensions

(mm)

|

Trolley Dimensions (mm)

|

Approx. Shipping

Weight

(Kg)

|

|

ltr

|

H

|

D

|

W

|

D

|

H

|

|

BVL-150 (F)

|

32

|

50

|

Cartridge

|

2.14

|

0.75

|

6

|

385

|

200

|

400

|

500

|

800

|

55

|

|

BVL-250 (F)

|

32

|

50

|

Cartridge

|

2.14

|

0.75

|

15

|

480

|

314

|

400

|

500

|

800

|

55

|

|

BVL-350 (F)

|

38

|

50

|

Cartridge

|

2.65

|

1.3

|

15

|

480

|

314

|

400

|

500

|

800

|

60

|

|

BVL-450 (F)

|

38

|

50

|

Cartridge

|

3.9

|

1.75

|

15

|

480

|

314

|

420

|

500

|

860

|

75

|

|

BVL-725 (F)

|

50

|

50

|

Cartridge

|

8.0

|

4

|

30

|

695

|

314

|

500

|

510

|

940

|

100

|

|

BVL-1000 (F)*

|

50

|

63.5

|

Cartridge

|

8.3

|

4

|

30

|

695

|

314

|

680

|

1130

|

1270

|

150

|

|

BVL-1500 (F)*

|

50

|

63.5

|

Cartridge

|

12

|

5.5

|

60

|

1085

|

314

|

680

|

1130

|

1270

|

165

|

|

BVL-2000 (F)*

|

63.5

|

63.5

|

Cartridge

|

15.6

|

7.5

|

60

|

1085

|

314

|

680

|

1130

|

1270

|

200

|

|

*Compressed air required 5 to 6 bar

|

BVL-1000 (F) / 1500 (F) / 2000 (F) — Without caster wheels

|