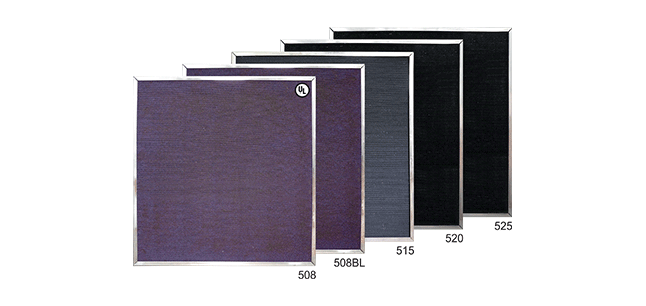

Honeycomb Chemical Filter – DRISORB™ Series

Macroporous desiccant-based fluted media with low pressure drop

Our Airgineers Can Help You Select The Right Product!

Contact Us

Macroporous Matrix Technology

High Structural Strength

High Chemical Impregnation

Customisable and Reliable

Extruded honeycomb chemical filters are fragile, use mainly active carbon, have limited bulk density, and have a higher pressure drop. In contrast, formed honeycomb filters are structurally robust, offer various filtering agents, boast high bulk density, and maintain a lower pressure drop. Formed filters excel in impregnate loading and efficiency, and have a longer mean time between replacements (MTBR).

The advantages of DRISORB™ Honeycomb Chemical Filter are: 1. Versatile Sizing: Available in depths ranging from 1″ to 12″ in both standard and custom filter sizes. 2. Extended Lifespan: Offers a longer filter life, resulting in a higher Mean Time Between Replacement (MTBR). 3. Compliance: Meets ASHRAE 145.2P and ISO 11155-2 standards for air filtration. 4. High Capacity: Provides a very high capacity for effective removal of contaminants. 5. Low Pressure Drop: Maintains a very low-pressure drop, enhancing airflow efficiency. 6. Impregnation Options: Available with various impregnants for versatile chemical filtration. These advantages collectively make DRISORB™ Honeycomb Chemical Filter an efficient and reliable choice for gas phase filtration systems.

Yes, Bry-Air chemical filters are replaceable. Routine replacement is necessary as these filters have a finite lifespan and become saturated with contaminants over time to ensure continued effective air filtration.

Bry-Air chemical filters i.e., DRISORB™ Honeycomb Chemical Filters have a variable lifespan. It depends on factors like the type and concentration of pollutants in the air.

Bry-Air Honeycomb Chemical Filter is available with various impregnants, allowing it to be tailored to specific filtration needs. Some common types of impregnants are Potassium Permanganate (KMnO4), Potassium Hydroxide (KOH) and Phosphoric Acid (H3PO4).

To choose the right impregnant for your application, identify the specific contaminants, assess their concentration levels, consider chemical compatibility, evaluate filtration efficiency requirements, account for operating conditions, ensure regulatory compliance, and consult with filtration experts or the manufacturer (like Bry-Air). This comprehensive assessment will help you select the most suitable impregnate to effectively remove the targeted contaminants and optimize your filtration system’s performance.

Maintenance requirements for the Bry-Air Honeycomb Chemical Filter include periodic inspections to assess filter saturation, monitoring pressure drop, and adhering to recommended replacement intervals. Regular maintenance ensures the filter continues to effectively remove contaminants. Maintenance schedules may vary based on specific applications and contaminant levels, but following manufacturer guidelines is essential to maintain air quality and system performance.

To confirm that the Bry-Air Honeycomb Chemical Filter suits your requirements, identify your specific contaminant types and concentrations. Bry-Air with a wide range of service networks offers services from pre-installation assessment of the environment to the installation of suitable products. Additionally, it provides a post-installation evaluation of the remaining media life.

The efficiency of the Bry-Air Honeycomb Chemical Filter in removing contaminants depends on the impregnant used and the specific application. It is designed to offer high efficiency in adsorbing or neutralizing a wide range of gaseous contaminants, including odours and volatile organic compounds (VOCs). Efficiency levels can vary based on factors such as the impregnant type, concentration levels, and operating conditions, but Bry-Air’s filters are engineered for effective contaminant removal. Specific efficiency data can be obtained through consultation with Bry-Air’s technical experts for your particular application.

The lifespan of the Bry-Air Honeycomb Chemical Filter depends on various factors, including the type and concentration of contaminants, operating conditions, and the specific impregnant used. Typically, these filters can last anywhere from several months to over a year before requiring replacement. Regular monitoring and adherence to recommended replacement intervals, as provided by Bry-Air, are essential to ensure continued effective filtration and contaminant removal.