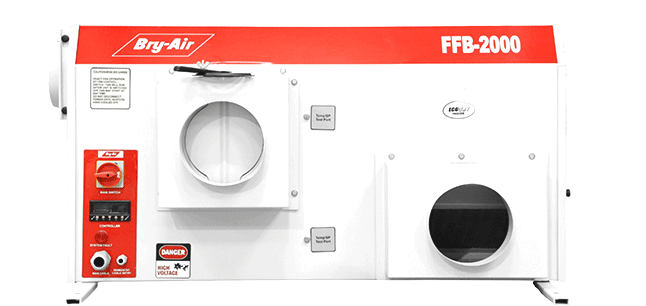

Compact Desiccant Dehumidifier – FFB Series

CNC fabricated with powder coated finish (ranging from 170 CMH to 4,500 CMH)

Our Airgineers Can Help You Select The Right Product!

Contact Us

Compact yet robust

Small footprint

Largest capacity range

Lowest volume/ Weight per CMH

The Bry-Air Compact Desiccant Dehumidifier FFB Series offers compact, lightweight, and cost-effective solutions, eliminating the need for extensive floor space. With a small footprint, it integrates commercial unit aesthetics with industrial ruggedness. Featuring high-performance desiccant rotors and optional stainless steel construction, it’s versatile, applicable to diverse industries. Its largest capacity range (170 CMH to 4500 CMH) suits pharmaceuticals, food processing, electronics, and more. Simple operation and the patented EcoDry rotor technology ensure efficient moisture control, making it an indispensable, little giant in industrial dehumidification, ideal for various applications worldwide.

The Compact Desiccant Dehumidifier FFB Series stands out from other desiccant dehumidifiers on the market due to its unique features:

Compact Design: The FFB Series is specifically designed to be compact, making it easier to place anywhere without requiring large floor space.

Dehumidification: Despite its small size, it packs a powerful punch, combining the small footprint of a commercial unit with the ruggedness of an industrial dehumidifier.

Lightweight and Cost-Effective: It is lightweight and cost-effective, making it suitable for small areas with a critical need for moisture control.

Versatility: The FFB Series has a wide range of industrial applications, offering solutions for various industries such as pharmaceuticals, food processing, electronics, defense, and more.

High-Performance Features: It incorporates high-performance fluted metal silicate desiccant-synthesized rotors and provides options for stainless steel construction, ensuring durability and effective moisture control.

Flexible Placement: It can be placed indoors or outdoors, including mounting options, offering flexibility in installation.

Largest Capacity Range: The FFB Series boasts the largest capacity range in Compact Dehumidifiers, catering to a variety of air volume requirements (170 CMH to 4500 CMH).

The various ranges of a Compact Desiccant Dehumidifier are as follows: